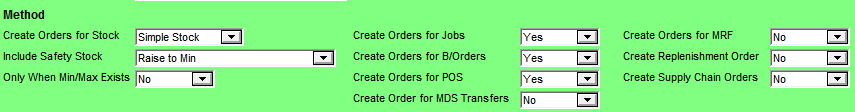

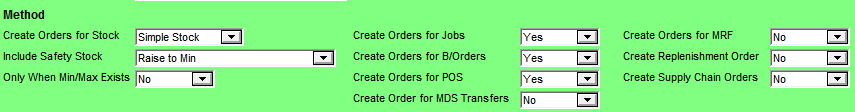

The methods you choose on the Automatic Purchase Order Header screen define what files are scanned and how the quantity suggested is calculated to create the list of products to order.

Method Selection fields

To set your method of creation:

Refer to "Maintaining the Automatic Purchase Order Header".

|

|

Field |

Value |

|---|---|---|

|

|

Create Orders for Stock |

Select the type of stock you want considered for auto purchasing. Your options in this field are:

Micronet scans all orders and adds those that match your selection criteria to the suggested list of items to order.

Micronet scans all orders and adds those that match your selected order class to the suggested list of items to order, and where:

The suggested quantity is calculated by applying:

|

|

|

|

Reference

|

|

Include Safety Stock |

This is the suggested quantity on which to base the calculation. Options are:

Raise to Max when Avail <= Min – uses the maximum stock when the free stock is less than or equal to the minimum stock as the suggested quantity, before applying any overriding factors. |

|

|

|

Reference For more information about the effects of your selection in the Include Safety Stock field, see the next section "How Micronet Calculates Stock Purchase Quantities for Automatic Purchase Orders". |

|

|

Only When Min/Max Exists |

2.8 Feature If you selected Raise to Min, Raise to Max or Raise to Max When Avail < Min in the Include Safety Stock field, select Yes if you only want Micronet to consider items for which minimum and maximum stock levels have been set. Select No if Micronet should ignore any items that don't have minimum or maximum stock levels set. |

|

|

Create Orders for Jobs |

Select Yes if you want Micronet to create automatic purchase orders for Micronet Job Costing (MJC) jobs. Micronet scans through the MJC jobs and adds those that match your selection criteria to the suggested list of items to order, before applying any overriding factors. MJC job items are only added to the automatic purchase order if:

|

|

|

Create Orders for B/Orders |

Select Yes if you want Micronet to create automatic purchase orders for backorders. Micronet scans all backorders and adds those that match your selection criteria to the suggested list of items to order, before applying any overriding factors. Backordered items are only added to the automatic purchase order if:

|

|

|

Create Orders for POS |

Select Yes if you want Micronet to create automatic purchase orders for Enhanced Point of Sale (enPOS) orders. Micronet scans through the enPOS orders and adds those that match your selection criteria to the suggested list of items to order, before applying any overriding factors. enPOS order items are only added to the automatic purchase order if:

|

|

Create Order for MDS Transfers |

2.8 Feature This field only applies if you have the Supply Chain module activated in your Micronet system – see "Edit - Program - Supply Chain Config (v2.8)". Select Yes if you want Micronet to consider items included in supply chain transfers in the automatic purchase orders. Micronet scans through the transfers created by other warehouses and adds those with a status of Auto PO Request to the suggested list of items to order, before applying any overriding factors. |

|

|

|

Create Orders for MRF |

Select Yes if you want Micronet to create automatic purchase orders for Micronet Roll Forming (MRF) orders. Micronet scans through the MRF orders and adds those that match your selection criteria to the suggested list of items to order, before applying any overriding factors. |

|

Create Replenishment Order |

Select Yes if you want Micronet to create replenishment orders. Micronet scans invoices created through MDS and enPOS and adds those that match your selection criteria to the suggested list of items to order, before applying any overriding factors. Orders are only added if:

|

|

|

Create Supply Chain Orders |

2.8 Feature This field only applies if your company is using supply chain procurement – see "Edit - Program - Supply Chain Config (v2.8)". Select Yes if you want Micronet to consider items included in supply chain orders in this automatic purchase order. Micronet scans through the orders created by other warehouses and adds those with a procurement type of Auto PO Request to the suggested list of items to order, before applying any overriding factors. Note that it does not order stock if a customer's order is on debtor hold. |

Refer to "Automatic Purchase Order Header - Selection Criteria" and "Automatic Purchase Order Header - Overriding Factors".

Refer to "Generating the List of Items to Order".